In the mining and bulk material handling industry, safety and operational efficiency are non-negotiable. For sites operating large-scale conveyor systems, keeping equipment clean, compliant, and safe to maintain is an ongoing challenge. This is where the right conveyor belt cleaners—designed with both AS4024 compliance, maintenance and user convenience in mind—can make a measurable difference.

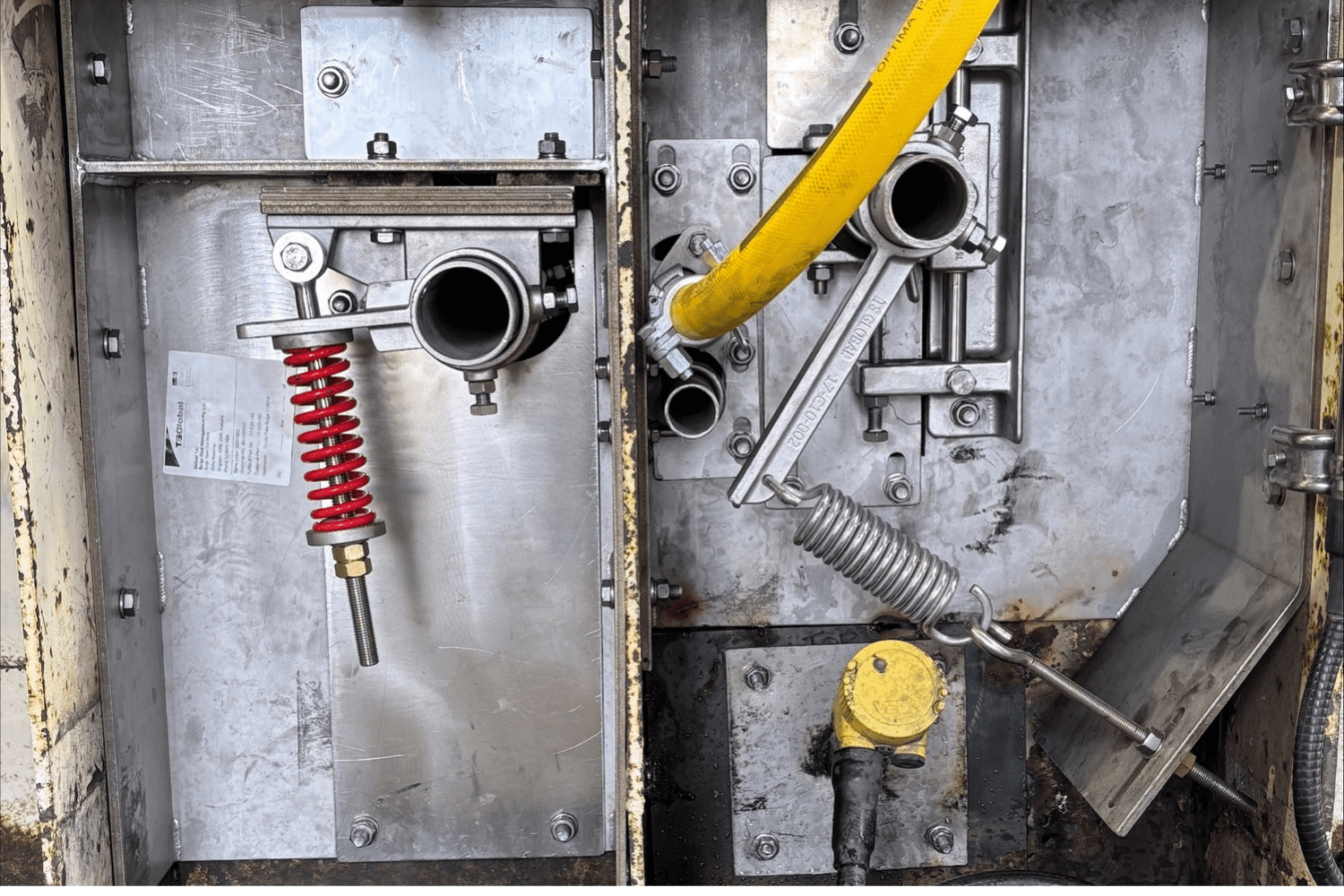

Before TS Global was engaged, the pictured, existing cleaner system was severely corroded and underperforming (installed by another provider).

This article explores why conveyor belt cleaners (also known as belt scrapers) are essential for productivity, the importance of adhering to the AS4024 machinery safety standard, and how features like retractable cleaners and guarded inspection hatches improve both maintenance and safety outcomes.

Understanding AS4024 and Its Critical Role in Conveyor Safety

AS4024 – Safeguarding of Machinery – is more than a safety guideline; it’s a comprehensive framework designed to protect workers from hazards such as entanglement, crushing, nip and shearing points. For conveyor belt cleaning systems, meeting AS4024 requirements ensures that guards, inspection points, and servicing processes minimise direct exposure to moving parts.

Why AS4024 compliance matters:

• Protects workers from high-risk mechanical hazards.

• Reduces legal and financial risks from accidents.

• Improves the safety culture across the site.

• Ensures consistency in equipment design and maintenance practices.

Choosing AS4024-compliant conveyor accessories is an investment in both workforce safety and operational reliability.

Retractable Belt Cleaners and Spray Poles: A Step Change in Maintenance Safety

One of the most impactful design innovations for conveyor maintenance is the retractable conveyor belt cleaner paired with a retractable spray pole. These systems slide out from under the conveyor, providing fast and safe access to cleaner blades and spray nozzles, eliminating the need for personnel to enter confined spaces like chutes, or conveyor underpans.

Benefits of retractable systems:

• Minimised exposure to moving parts – Operators can service belt scrapers without entering confined or cramped spaces.

• Easier inspections – Inspection and cleaning can be carried out behind integrated guarded hatches, meeting AS4024 standards.

• Carry-back reduction – Cleaner belts mean less spillage, faster clean-up, and lower operating costs.

• Faster servicing – Blade changes and adjustments can be made quickly, reducing conveyor downtime and maintenance costs.

• Better ergonomics – Maintenance can be done from safe, stable positions, reducing slips, trips, and strain injuries.

By reducing carry-back, these systems not only keep belts cleaner but also reduce the manual labour required for clean-up, offering a rapid return on investment.

TS Global was called on to deliver a new standard in belt cleaning—a fully guarded, AS4024-compliant system designed for safer maintenance, superior performance, and long-term reliability. Pictured above.

Guarded Inspection Hatches: Safer, Faster, Smarter Maintenance

Guarded hatches are another key feature that improves inspection efficiency without compromising safety. Built into the belt cleaner structure, they allow visual checks and minor servicing while keeping moving parts safely enclosed.

Advantages include:

• Safe and quick inspections – No need for full conveyor shutdowns or dismantling.

• Proactive maintenance – Frequent checks help identify issues before they escalate.

• AS4024 compliance – Guarded hatches maintain safety integrity even during servicing.

This proactive approach to inspection not only extends the life of belt cleaners but also reduces unexpected downtime.

TS Global was called on to deliver a new standard in belt cleaning—a fully guarded, AS4024-compliant system designed for safer maintenance, superior performance, and long-term reliability. Pictured above.

Conclusion

For material handling operations, AS4024-compliant retractable conveyor belt cleaners and spray poles offer a powerful combination of safety, efficiency, and ease of maintenance. By reducing carry-back, improving inspection access, and eliminating the need for confined space entry, these systems protect both people and productivity.

Investing in compliant, well-designed conveyor cleaning systems is not just good practice, it’s essential for maintaining safe, efficient, and profitable operations.